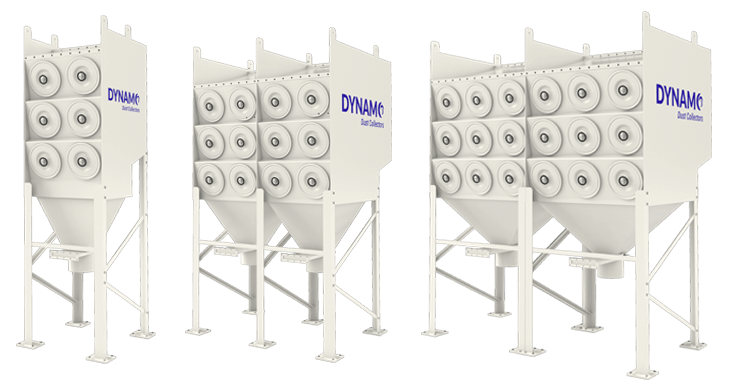

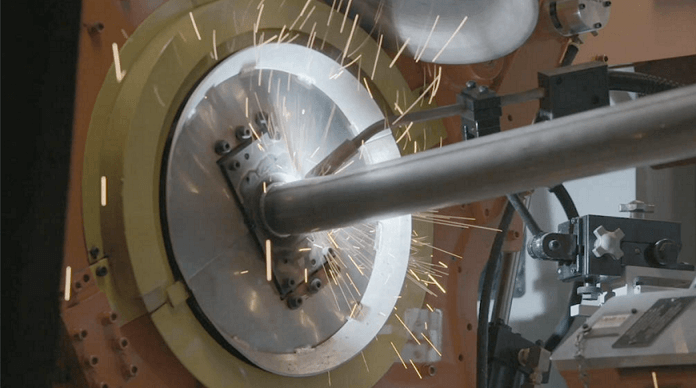

A global automotive parts manufacturer faced with unique safety and health requirements needed help establishing a safe, clean air working environment. The machine operators weld up to 8 hours a day and rely on dust collectors to extract and filter contaminated air.

Before industrial dust collectors, these welders were faced with a system that was inefficient and costly, required frequent filter changes, and operated loudly.

Dynamo Dust Collectors come equipped with MAC pulse valves. These valves are optimized for harsh environments and allow our dust collectors to provide a strong, quiet, and reliable solution for industrial applications.

The high impact pulse of MAC valves results in less frequent intervals and system operation which saves energy and cuts filter changes down by up to 30% when compared to competitors!

Once Dynamo Dust Collectors were installed, the machine operators noticed a drastic change in the facility's air quality.

Dynamo industrial dust collectors are constructed of high-quality, American made parts that are backed by great warranties to prove our commitment to customer satisfaction.

Each detail of Dynamo dust collectors have been chosen by industry experts to ensure the highest level of quality. Housed in the heaviest steel construction, MAC Pulse Valves, Mechanovent blowers, and Nanofiber Filters work together to provide the most efficient dust collection solution.

✓ 20-30% longer filter life vs. competitors

✓ MAC Pulse Valves as standard

✓ Meets NFPA 652 & 654 explosion standards and OSHA's safety requirements

Call Us Today -or- Request A Quote! Request a Quote