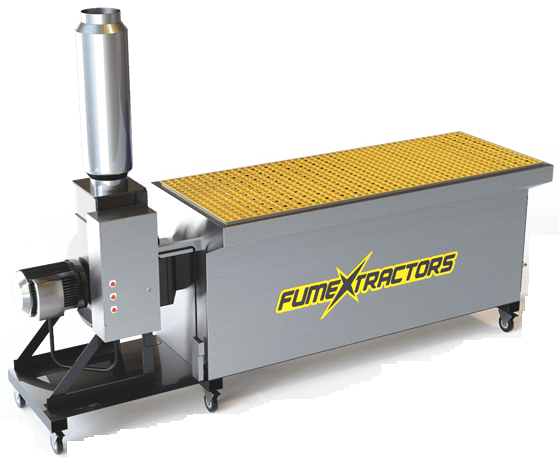

Installing dry downdraft tables as part of your production process will guarantee that fine dust particles, smoke, and fumes are captured at the source. FumeXtractors Dry Downdraft Tables are ideal for metalworking, sanding, cutting, and mixing applications.

Dry downdraft tables are available at mid-range prices making it easy to purchase and add more systems as your business grows. FumeXtractors dry downdraft tables are powerful to handle the toughest machining applications and comply with all regulatory guidelines.

Benefits:

To keep combustible dust under control, it must be captured directly at the source. FumeXtractors Wet Downdraft Tables capture and contain explosive dust — using water to bond and neutralize them.

The NFPA 484 Standard for Combustible Metals prohibits collecting aluminum, magnesium, and other combustible metal dust using dry downdraft tables. If your application or machining process involves metals that can create explosive dust, such as aluminum, magnesium, titanium — a wet downdraft table is right for you.

Benefits:

Call Us Today -or- Request A Quote! Request a Quote