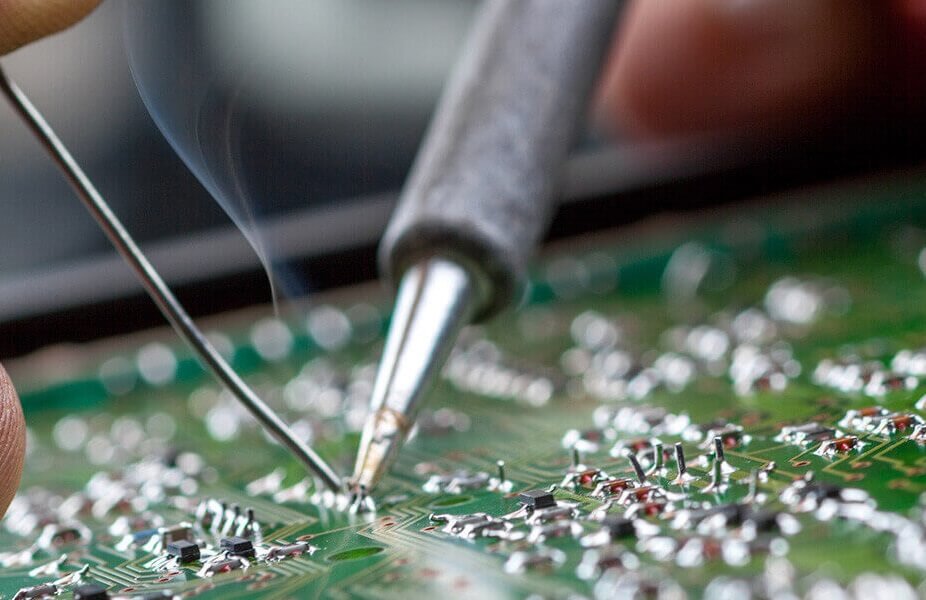

Soldering is used to join two (or more) workpieces by melting and flowing a filler metal into the joint to form a permanent connection between components. During the soldering process, toxic fumes are released increasing the risk of employee injuries, equipment malfunctions, and lost production time.

The dangers of soldering fumes are caused by the flux. The soldering flux cleans pre-joined surfaces and increases the flow of solder to create a quality joint and prevent oxidation. If not properly captured, the fumes developed during this process will enter breathing zones and accumulate on equipment and in the workplace presenting health and safety risks.

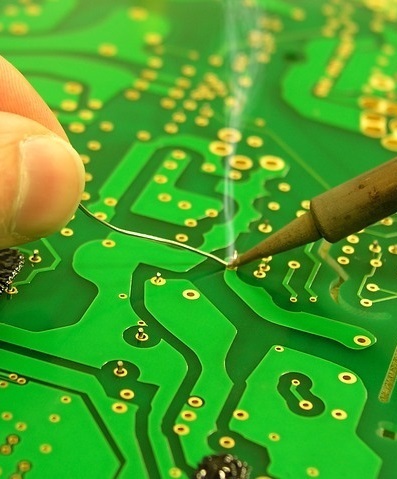

Soldering processes must be equipped to meet regulatory guidelines and filter contaminated air at the source. When soldering fumes are not captured at the source, they enter the air stream and create risk of overexposure.

Soldering fume also accumulates in the work environment, increasing the risk of employee injury, equipment malfunction, and lost production time. Without appropriate air filtration, wave solder, reflow, selective solder, and conformal coating operators are at risk of:

• Skin and eye irritation

• Allergies

• Bronchitis

• Sinonasal cancer

• And carcinogenic heart and lung diseases.

Air filtration systems provide a secondary method to capture contaminants from soldering that aren't removed by the primary extraction solution. Air filtration systems for soldering work by utilizing a centrifugal type blower and specializes filter media to capture contaminants as they are drawn in.

By combining air filtration with an extraction system, you can establish a safe, clean air working environment. For more information about air cleaners for solder fume removal, get in touch with us today.

Learn More

Call Us Today -or- Request A Quote! Request a Quote