During the handling and processing of powders and other dry bulk materials, dust becomes easily disturbed and can contaminate the airstream if uncontrolled.

Overexposure to powder handling dust can irritate airways, cause allergic reactions and respiratory illness, and worsen existing lung conditions.

Because powder handling and processing spreads dust quickly, employers should evaluate the work processes, cargo handling, and problem areas before choosing a dust collection solution.

By installing a dust collector with the proper industrial cartridge filters, you can help prevent injury risks, equipment malfunction, and lost production time by ensuring a clean airstream in the facility.

Using a blower to develop negative pressure, dust collectors draw contaminated air through a series of filter media, such as industrial cartridge filters, until it's clean.

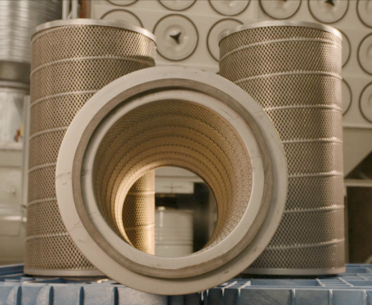

Cartridge filters are pleated cylindrical or oval filter elements made from fabrics like polyester or cellulose. As the contaminated air passes through these filters, dust particles are trapped on the surface, allowing clean air to pass through. Their large surface area and compact design enable high air flow and efficient particle capture.

Periodic pulse-jet cleaning dislodges accumulated dust from the cartridge filters, prolonging their service life and ensuring consistent filtration performance.

Air Cleaning Specialists' industrial cartridge filters provide a high-quality solution for facilities faced with the dangers of powder handling dust.

The blower in a dust collection system must be properly sized to guarantee the required airflow is met and to overcome pressure drops and losses across the filter media.

Once the air has been filtered and cleaned by the industrial cartridge filters, it can be safely released back to the work environment or exhausted outside, away from the facility. This ensures employee safety, proper equipment functioning, and improved overall production by maintaining a clean airstream within the industrial facility.

At Air Cleaning Specialists, we offer you a direct path to high-quality dust collector cartridge filters, often sourced from the same manufacturing lines as the original equipment manufacturers (OEMs).

By eliminating the middleman, we can provide you with high-quality filters at more competitive prices. Before introducing any new filter to our product line, we subject it to rigorous long-term testing to ensure it meets or exceeds the performance standards set by the OEMs.

When you purchase from us, you can be confident that you're receiving filters that have undergone stringent quality checks and are designed to deliver exceptional filtration efficiency. Contact our specialists to learn more or to get started on your free quote for industrial cartridge filters!

Call Us Today -or- Request A Quote! Request a Quote