AIS, a construction equipment dealership for John Deere and Komatsu, specializes in fabricating attachments and modifying and repairing heavy equipment for customers.

They have anywhere from 3-6 machine operators working at one time and were experiencing challenges with plasma cutting and welding smoke. Their primary issue was a thick haze that wouldn't clear for up to an hour after plasma cutting. During the welding process, smoke would also fill the facility up.

Our team developed an efficient airflow pattern and installed Blue Ox OX3000 and OX3200 air cleaners. The smoke that filled up the facility during welding processes has been eliminated! And the plasma cutting haze has been greatly improved - generally, the air is clear within 5 minutes of cutting.

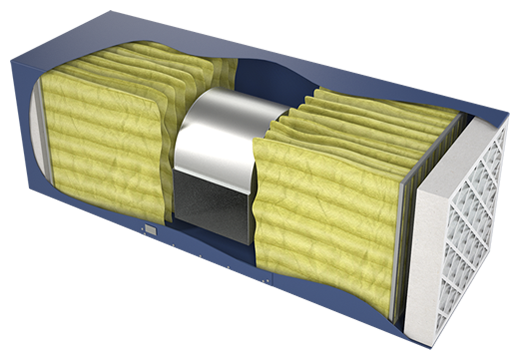

Blue Ox OX3200 air cleaners feature a T-pattern airflow with inlets on both ends and exhausts in the middle.

These air filtration systems feature a dual set of micro-glass fiber disposable filters to provide more filter area and allow the units to operate with considerably less static pressure. The lower airflow-to-filter ratio provides higher efficiency and longer filter life.

CFM: 3000

Airflow: T Pattern Airflow Unit

Filters Included:

• (2) 24" x 24" x 4" 35% Pleated Fiber Pre-Filter

• (2) 24" x 24" x 22" 65% 8 Pocket Bag Filter

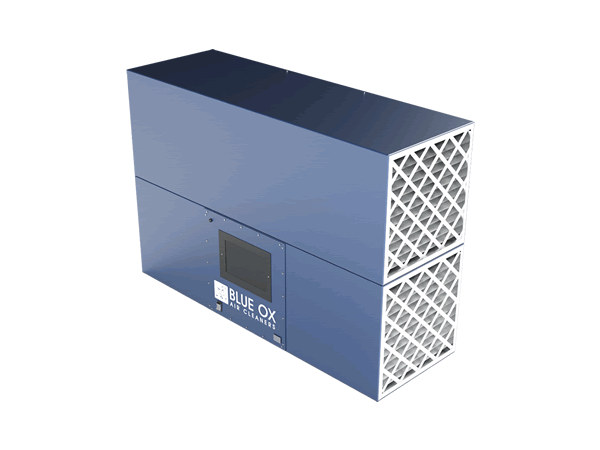

Blue Ox OX3000 air cleaners feature a T-pattern airflow with an inlet on both ends and exhausts from the center.

These multi-unit setups have higher filter cloth-to-air ratios, resulting in significant maintenance cost savings and fewer units require. They are primarily designed for larger installs where there is a heavy contamination load and a lot of area to be filtered and cleaned.

CFM: 3200

Airflow: T Pattern Airflow Unit

Filters Included:

• (4) 24" x 24" x 4" Pleated Fiber Pre-filter

• (4) 24" x 24" x 22" 65% 8 Pocket Bag Filter

From Our Customers

Our problems with welding smoke during the welding process have been eliminated!

- Rick, AIS Construction Equipment

Call Us Today -or- Request A Quote! Request a Quote