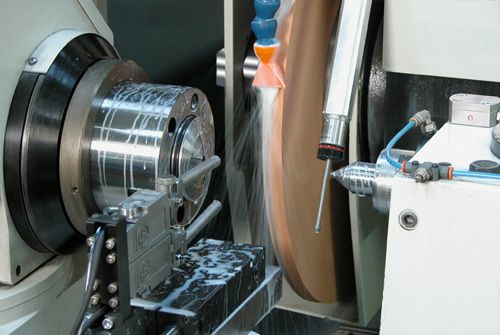

Machining process mist and smoke are produced when industrial machines are working at high speeds and using high coolant pressures during hot manufacturing processes.

Oil mist is a collection of droplets that become airborne when oil-based lubricants are used in the machining of metal and certain plastics, or in facilities where milling, grinding, or drilling takes place.

Oil smoke is composed of the same droplets as oil mist. The main difference between the two is that oil smoke particles are smaller and normally materialize into larger volumes.

Typically, both oil mist and smoke are developed during machining processes. When the droplets are larger they're considered to be an oil mist and when they're smaller, oil smoke.

Oil mist droplets are the same size as bacteria and range between 1-10 µm, the size of oil smoke particles range between 0.1–1 µm.

The most efficient way to collect oil mist and smoke is by extracting contaminated air at the source with an industrial collection system.

ScandMist collectors are designed for continuous operations in demanding airflow applications. From machining processes to heat treatment, ScandMist oil mist and smoke collectors accommodate wet to medium-wet, semi-dry and dry applications.

Learn More

Call Us Today -or- Request A Quote! Request a Quote